S Welding Technolog SAA – Aluminum E4043 Stick Electrode Rod 18 x 14 – (1 lb)

$22.95

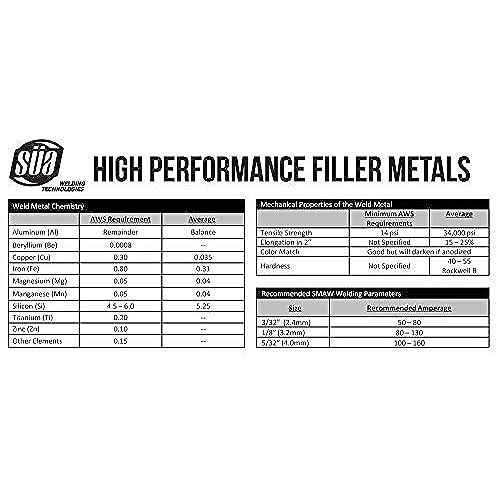

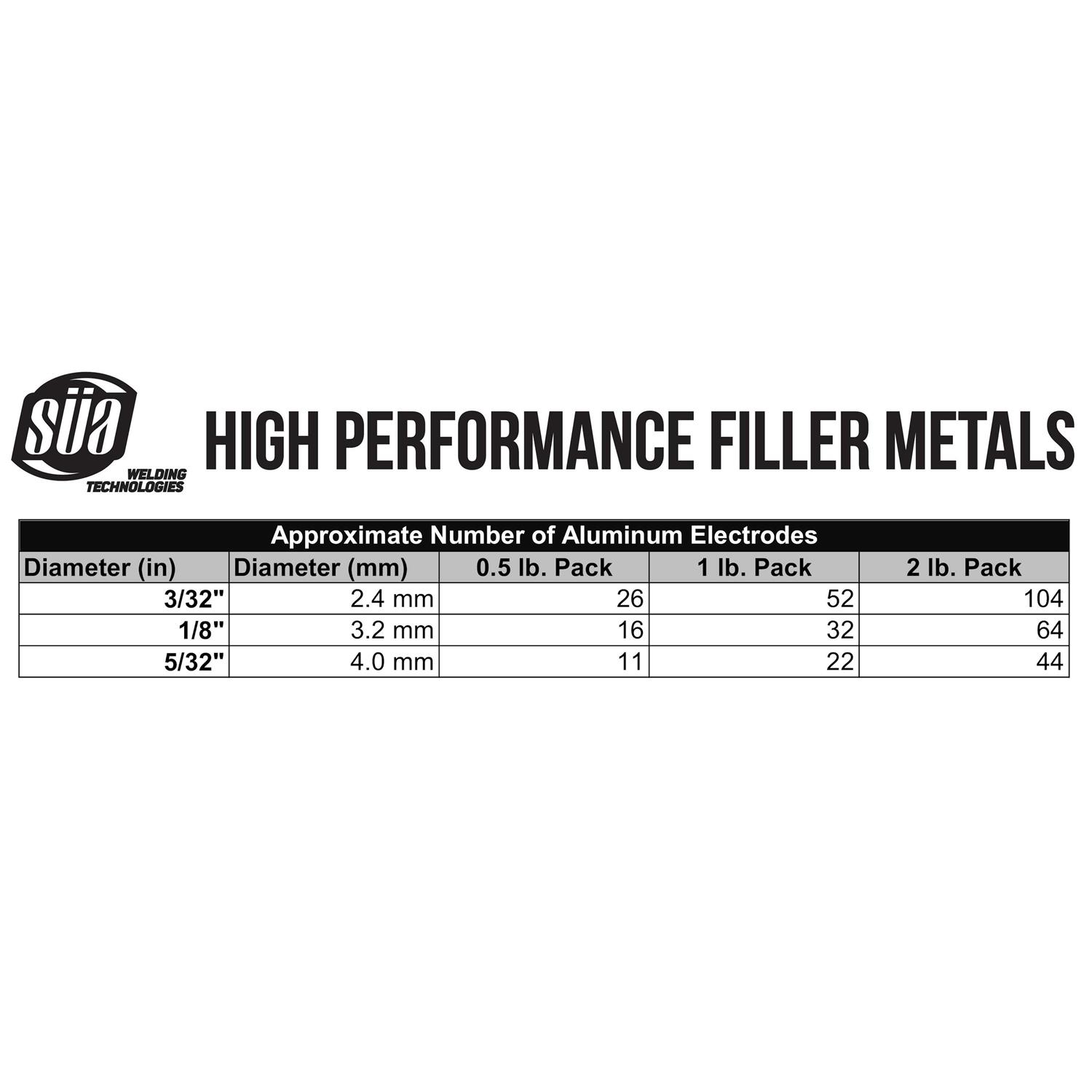

SÜA – E4043 is used for production or maintenance and repair welding on all weldable grades of aluminum sheets, plates, pipes, castings, and extrusions with a minimum of 3/32” thickness. Special extruded coating in this electrode is dense and without the air holes found in cheaper dip-coated electrodes and it provides a gas atmosphere to protect the arc. ***READ THIS: The images are for reference only. Please check Picture #2 for an approximate quantity of electrodes per pound*** Can be used as a SMAW-stick electrode or as an oxyacetylene brazing rod. Very easy to use with an exceptionally stable arc, operating at low amperages with a very minimal amount of spatter or fumes. Weld deposits are strong, dense, porosity-free with good color match and corrosion resistance. Good weldability; rapid ignition and re-ignition, little splashing, easy removal of oxides, the characteristics of the joints are particularly good. Good capillary fluidity. Commonly used on irrigation piping systems, refrigeration equipment, appliances, boat parts, ornamental aluminum parts, aluminum door or window frames, aluminum ladders, tanks, shelves, automotive, trucks or bus parts, machining errors, and building-up missing sections on castings, extrusions, and plates. These Electrodes are 14 inches long and are available in Sizes: 3/32″, 1/8″ and 5/32″ – Available Packages: 0.5 Lb, 1 Lb and 2 Lb – Select your option from the Size Menu – Check Picture #2 for an approximate number of electrodes per pound. Instructions: Clean the weld area thoroughly so it is not contaminated with iron, rust, oil, grease, etc. Thicker sections should be beveled to a 60° Vee. Align the parts to be welded by tacking the joint(s). Preheating thicker sections to 350°F will flatten the weld bead and reduce the amperage needed. Use DC+ (reverse polarity), hold the electrode at a 90° angle to the work piece, maintain a short arc length and move rapidly. The weaving technique is not recommended because of the faster travel speeds required when welding aluminum. Allow the part to air cool and remove all slag using a stainless steel brush before making additional passes. When finished, allow the part to cool down to about 200°F and remove flux residue with warm water and a stiff stainless steel brush. A 10% sulfuric acid and hot water solution applied with a stainless steel brush will give a clean, more polished appearance. Notes: When using an oxyacetylene torch to braze, set torch to a carbonizing flame and carbonize the part, then readjust to a neutral flame and heat the entire part until the carbon residues fade; then apply E4043.

Reviews

There are no reviews yet.